Key Features Of KELVIN M200

Real-Time Location Tracking

Temperature Detection

Tamper & Shock Recognition

Flight Mode

(IATA/FAA Compliant)

Real-Time Alerts

PDF Reports

View The Data On Our Platform

Geofencing

Monitoring Cargo

Anytime, Anywhere

By utilizing location tracking, KELVIN M200 ensures that an asset is never lost.

Reliably locate an asset in any environment via KELVIN M200's real-time location tracking capability. The asset tracking solution and its connectivity capabilities aim to maximize the visibility of an asset on the network, helping to avoid detection problems faced in closed spaces such as warehouses. Achieve greater visibility and improve your operational efficiency with reliable real-time location tracking.

Temperature

Detection

Protect your temperature-sensitive high-value assets with accurate temperature monitoring.

With an operating range of -20 to 60 degrees Celsius, KELVIN M200 accurately monitors the temperature of an asset. Real-time data is collected on temperature with updates sent to the cloud every 30 minutes. Real-time data is accessible via the dashboard, with alerts sent via email/SMS when an asset’s temperature falls outside its specific threshold value.

Flight Mode

Maintain data storage throughout a journey with KELVIN M200's automatic in-flight mode.

Following IATA regulations, the asset tracking solution utilizes machine learning algorithms to detect when an asset is in flight. During this time, the data logger enters sleep mode, while maintaining data storage throughout the journey. On landing, KELVIN M200 automatically wakes and resumes data transfer.

Tamper and Shock

Recognition

Monitoring the safety and security of an asset is crucial while in transit.

KELVIN M200’s light and shock sensors enable the user to take the appropriate actions to protect an asset’s security. Along with an accelerometer to monitor for violent shocks, light sensors can detect if a package has been opened during transit. Data is transmitted and stored on the cloud, with real-time visibility on the dashboard.

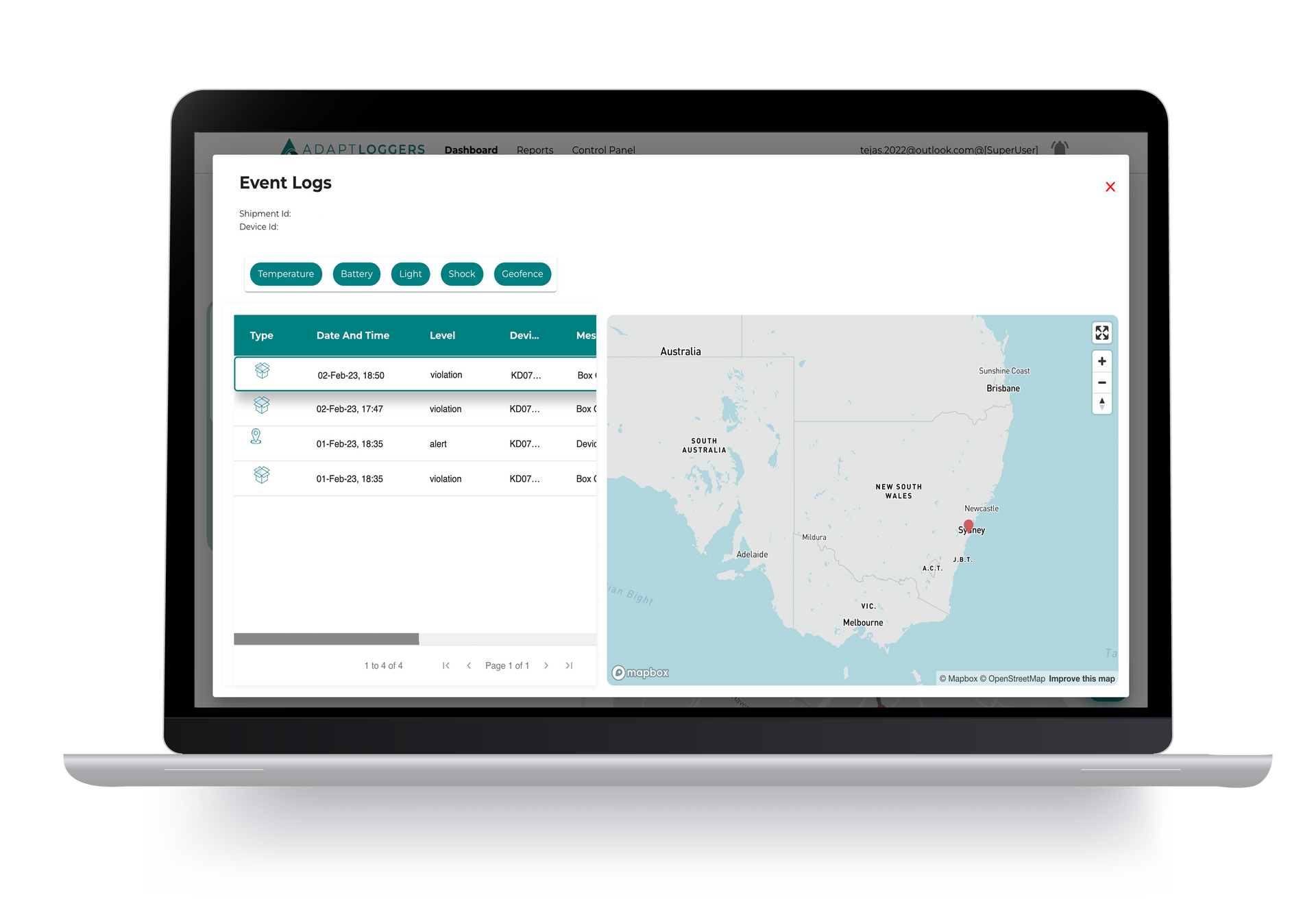

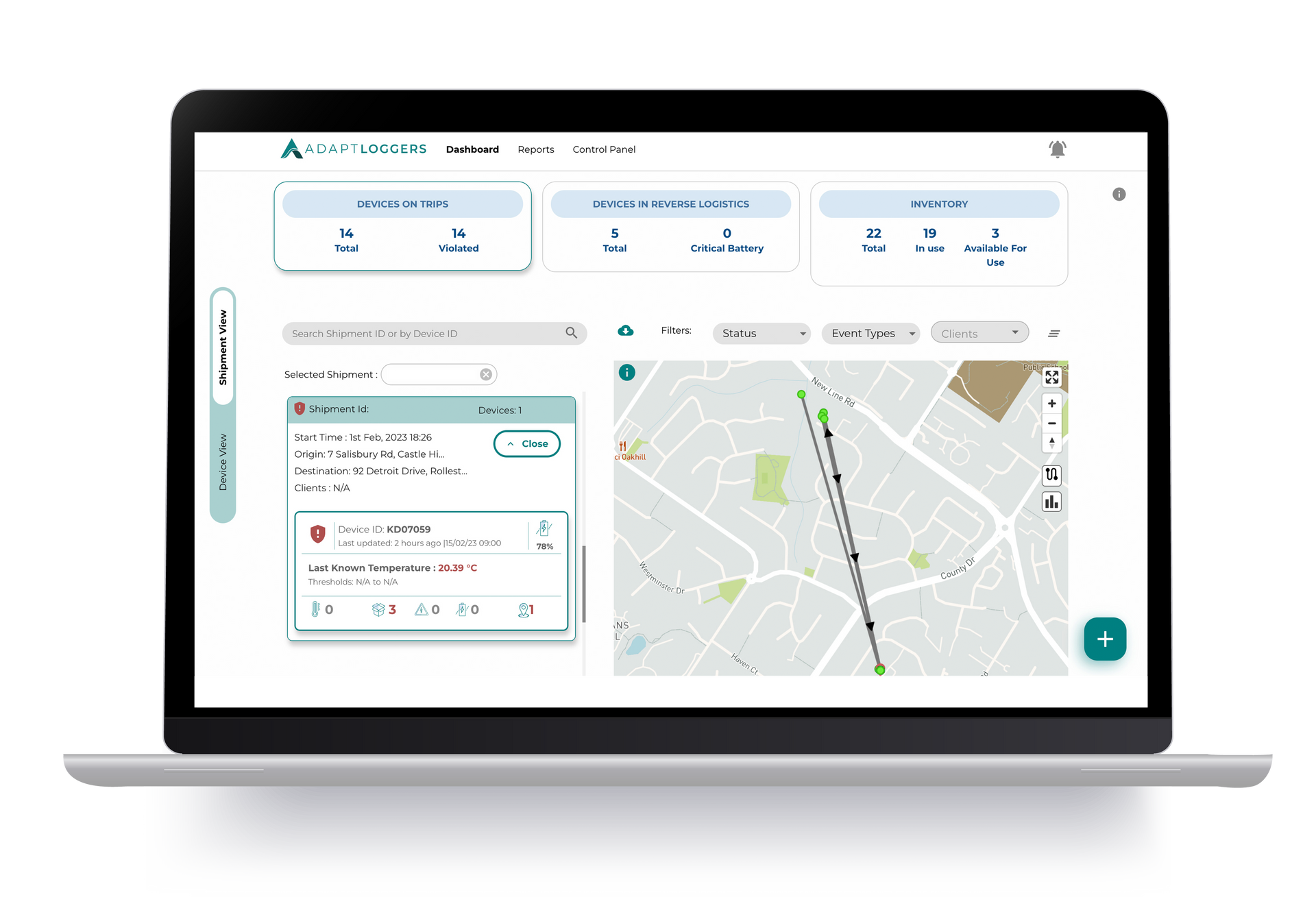

The KELVIN Dashboard

Sync every KELVIN M200 device to the secured cloud portal for automatic tracking of every shipment along with timely alerts and comprehensive digital reports.

CONFIGURE

CONFIGURE ACCORDING TO YOUR REQUIREMENT USING OUR PLATFORM

PAIR

TRACK

VIEW THE DATA ON OUR PLATFORM

Download KELVIN M200's

Technical Datasheet

Real World Problems Solved By KELVIN M200

Biopharmaceutical waste

is 25% of global production each year

Many pharmaceuticals react to fluctuations in light, temperature, vibration, and shocks. Such incidents make some pharmaceuticals not only ineffective but harmful and possibly even life-threatening. Monitoring the temperature and timing of shipments in real-time along the supply chain confirms compliance as much as it detects weaknesses and errors as soon as they happen and increases supply chain visibility.

Food and beverage waste

is 1/3 of global production each year

Due to the sensitive nature of perishable food, a lot can go wrong during the cold chain. Damage, temperature excursions, and contamination are a huge concern for the food and beverages industry. The industry is under stricter food transport safety regulations than ever before under the FDA’s Food Modernization Act (FSMA). By utilizing an asset-tracking solution to monitor temperature-sensitive assets during the cold chain greater operational efficiency can be achieved.