The Ultimate Guide To Cold Chain Risk Management

In the world of temperature-controlled logistics, the cold chain stands as a critical link that ensures the safe and timely delivery of temperature-sensitive goods. From lifesaving vaccines to fresh produce, the cold chain plays a pivotal role in maintaining the integrity of products that rely on controlled temperature environments. In this comprehensive guide, we'll dive deep into the world of Cold Chain Risk Management, exploring the challenges and solutions to help you safeguard your supply chain.

Cold Chain Risk Management is not just a buzzword; it's a critical aspect of ensuring that your products reach their destination in the right condition. Challenges associated with cold chain logistics cause $35 billion in waste annually, highlighting the need for more effective risk management.

First, let's gain a better understanding of what cold chain logistics entails and why it's such a critical component of the cold chain sector.

Table Of Contents

1. What is Cold Chain Logistics?

2. What is Cold Chain Risk Management?

3. Risks in the Cold Chain Industry

Temperature Variations and Their Impact

Unexpected Disruptions and Their Consequences

High Costs

The Global Impact of Cold Chain Risks

4. Comprehensive Guide to Cold Chain Risk Management

A. The Cold Chain Risk Assessment

Identifying Vulnerabilities

Analyzing Potential Threats

Evaluating the Impact of Risks

B. Real-Time Monitoring Solutions: Navigating the Path to Risk Mitigation

Adapt Ideations' KELVIN IoT Monitoring Track & Trace Devices

PIXEL Temperature Data Loggers for Cold Storage

C. Cold Chain Risk Mitigation Strategies: The Four Pillars of Success

Contingency Planning for Disruptions

Implementing Robust Standard Operating Procedures (SOPs)

The Role of Digital Transformation

Leveraging Technology for Proactive Risk Management

To Conclude

FAQs

1. What is Cold Chain Logistics?

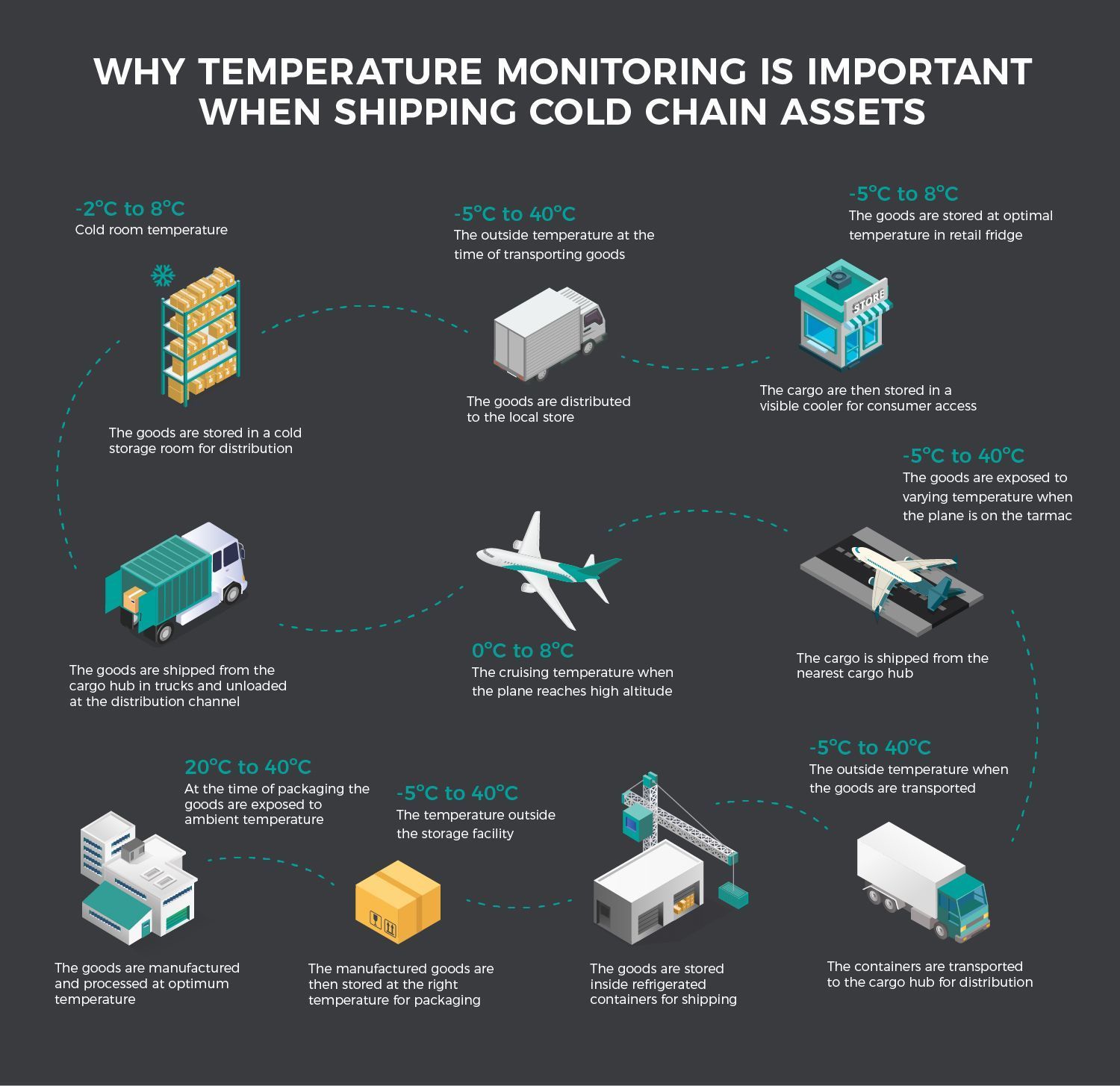

Cold Chain Logistics is the act of transporting temperature-controlled products, ensuring that they remain within specific temperature ranges from point A to point B. These temperature ranges can vary depending on the type of products being distributed. Therefore, understanding them is critical for effective Cold Chain Risk Management. Some common temperature ranges include:

- Deep Freeze (-28°C to -30°C): Reserved for the likes of seafood and meat exports, where maintaining ultra-low temperatures is vital.

- Frozen (-16°C to -20°C): Ideal for preserving meats and specific produce items during transit.

- Chill (2°C to 4°C): Best suited for fruit, vegetables, fresh meats, and dairy products.

- Pharma (2°C to 8°C): Essential for transporting medicines and vaccines.

- Cool-Chain (12°C to 14°C): Best for fresh produce, processed food, and over-the-counter drugs.

Maintaining these temperature ranges comes with its own set of challenges, such as cold chain breaches, shock exposure, tampering, and high costs. These challenges can often lead to product wastage and financial losses and even impact a company’s reputation.

Now, let's explore what exactly we mean by Cold Chain Risk Management.

2. What is Cold Chain Risk Management?

Cold chain risk management is a process that involves planning, producing, monitoring, and transporting temperature-sensitive products.

We can say it is the art and science of safeguarding temperature-sensitive products throughout the cold chain. The logistical focus of each stage in cold chain management is temperature control and monitoring.

Read more about -

Securing Your Cold Chain: A Comprehensive Guide to Cold Chain Management and Monitoring.

3. Risks in the Cold Chain Industry

Temperature Variations & Their Impact

Temperature variations can compromise the efficacy of temperature-sensitive products, leading to wastage, damage, and financial losses.

Unexpected Disruptions & Their Consequences

Disruptions in the cold chain can occur due to unforeseen events such as natural disasters, equipment failures, or logistical issues. These disruptions can have far-reaching consequences.

The Role of Cold Chain Risk Management in Mitigating Risks

Effective Cold Chain Risk Management is the key to minimizing these risks and ensuring that products maintain quality during transit.

High Costs

Cold chain logistics can be expensive due to the specialized equipment, infrastructure, and skilled staff required. Maintaining these high standards, however, is a necessity for the industry.

The Global Impact of Cold Chain Risks

With the global nature of supply chains, cold chain risks can have far-reaching consequences on the world stage. The need for effective risk management is more significant than ever.

4. Comprehensive Guide to Cold Chain Risk Management

To overcome the risks and challenges we have been discussing above implementation of a well-rounded approach is essential:

A. The Cold Chain Risk Assessment

Effective Cold Chain Risk Management begins with a comprehensive risk assessment. Understanding and addressing vulnerabilities in the supply chain is paramount to ensure the safe transportation of temperature-sensitive products.

Identifying Vulnerabilities

A comprehensive risk assessment begins with identifying potential vulnerabilities in your supply chain. These vulnerabilities can stem from many diverse factors like infrastructure, equipment, or external influences like weather conditions. In a world where unpredictability is the norm, acknowledging these weak points is the first step towards securing your cold chain.

Analyzing Potential Threats

Threat analysis involves a detailed examination of the risks associated with temperature variations and unexpected disruptions. It's crucial to note that temperature variations can lead to the loss of product efficacy and a significant financial impact. On the other hand, unexpected disruptions, as exemplified by natural disasters or equipment failures, can result in severe consequences for your supply chain.

Evaluating the Impact of Risks

Evaluating the potential impact of these identified risks is essential for prioritizing and strategizing risk mitigation. The statistics highlight that the global cold chain logistics market will reach $647.47 billion by 2028, underscoring the increasing significance of effective risk management. These figures should serve as a compelling reminder of the critical role that risk assessment plays in the cold chain.

B. Real-Time Monitoring Solutions: Navigating the Path to Risk Mitigation

Real-time monitoring is a game-changer in the world of cold chain logistics. We can track temperature-sensitive products' conditions in real-time during transportation, providing unparalleled visibility. This proactive approach ensures that you can identify and address any deviations in temperature, or other violations.

Let's zero in on how we at Adapt Ideations can revolutionize your cold chain risk management strategy.

Adapt Ideations' KELVIN IoT Monitoring Track & Trace Devices

We at Adapt Ideations offer KELVIN IoT Monitoring Track and Trace Devices that are designed for the demands of the cold chain. These devices provide a range of benefits, including:

- Real-time visibility at every stage of the supply chain, from the moment your temperature-sensitive shipments leave your facility.

- Proactive alerts for deviations in temperature and other vital metrics. This early warning system ensures that you can take corrective actions promptly, preventing product damage and loss.

- With these devices, you gain a vital edge in managing the complex world of cold chain logistics.

PIXEL Temperature Data Loggers for Cold Storage

We at Adapt Ideations have not left cold storage operations behind. Our PIXEL Temperature Data Loggers are tailored specifically for cold storage operations. We can help you with automating the monitoring of your cold storage spaces ensuring your products have been kept in the right conditions:

- Real-Time Visibility Within Cold Storages: Cold storage facilities require precise temperature management to ensure the quality and safety of stored products. PIXEL Temperature Data Loggers offer real-time visibility within these facilities, allowing you to monitor and maintain the desired temperature ranges.

- Ensuring Compliance & Sustainability: These data loggers play a crucial role in ensuring compliance with industry standards and regulations. By consistently maintaining the required temperature conditions, you meet regulatory requirements and contribute to sustainability efforts by reducing product waste.

Read more about - Master Cold Chain Compliance - Guide to Seamless US Logistics.

C. Cold Chain Risk Mitigation Strategies: The Four Pillars Of Success

When it comes to effectively mitigating cold chain risks, companies need to rely on a multifaceted approach. These four pillars are the foundation for building resilience and security in your supply chain:

Contingency Planning for Disruptions

In the unpredictable world of cold chain logistics, disruptions are a possibility. To ensure that your supply chain remains resilient, it's crucial to have a well-thought-out contingency plan. It includes identifying alternative transportation routes, securing backup equipment, and establishing clear protocols for dealing with unexpected events. This level of preparedness is essential in minimizing the impact of disruptions.

Implementing Robust Standard Operating Procedures (SOPs)

Your SOPs form the backbone of your risk management strategy. They should cover every aspect of the cold chain, from handling and packaging to monitoring temperature-sensitive products. By implementing rigorous SOPs, you can ensure that best practices are consistently followed, reducing the chances of human error and product damage.

The Role of Digital Transformation

In a rapidly evolving landscape, digital transformation is not a luxury but a necessity. It enables companies to optimize their supply chain operations, identify risks in real-time, and take immediate corrective actions. This proactive approach to risk management is the future of logistics.

Leveraging Technology for Proactive Risk Management

Technology solutions, like real-time monitoring devices, data analytics, and predictive tools, provide actionable insights into potential risks. These tools enable companies to predict issues before they occur, allowing for proactive measures to prevent problems and maintain the integrity of temperature-sensitive products.

Read more about -

Digital Transformation In Cold Chain Logistics: 7 Strategies You Need To Implement

To Conclude

In conclusion, effective Cold Chain Risk Management is not just a good practice; it's a necessity in today's complex supply chain landscape. Implementing real-time monitoring solutions like Adapt Ideations' KELVIN IoT Monitoring Track and Trace Devices and PIXEL Temperature Data Loggers significantly enhances your risk mitigation efforts.

The global market is evolving rapidly, and your ability to adapt to these changes and overcome challenges is crucial for the success of your business. Explore the benefits of using Adapt Ideations' products and ensure that your supply chain operates at peak efficiency while mitigating risks effectively.

This ultimate guide is your key to mastering cold chain risk management and ensuring the safe and efficient delivery of temperature-sensitive products. Adapt, overcome, and thrive in the world of cold chain logistics.

Enquire to find out more about our innovative solutions and how they can be utilized at enquiries@adaptideations.com

Share Our Post.

Awards & Recognition

Best Temperature Monitoring Solution Provider

Awarded by India Biologics & Vaccines Outstanding Industry Awards 2022

Adapt Ideations Recognised As A Supply Chain Leader

by Alcott Global on Supplify's Supply Chain Tech Map 2.0

Related Articles.